RERA-pro, a project headed by the Styrian firm Botres Global GmbH, is concerned with research leading to an integrated biorefinery to process residues on an industrial scale. Also involved in the project: Stipits Entsorgung GmbH and the Process Engineering study group in the Institute of Food Technology at the University of Natural Resources and Life Sciences, Vienna. The aim is to make high-grade products from organic waste, entirely emission-free, by means of system integration and linking together various pioneering technologies.

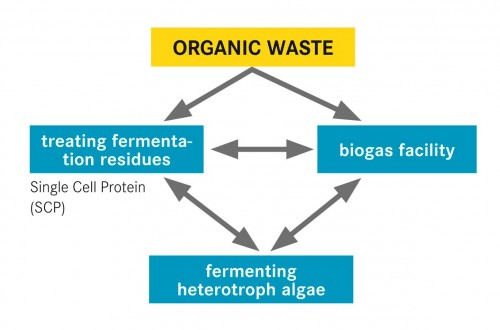

The approach adopted here differs from cascading strategies, as full use is made of the biomass in an integrated process, with no competition between energy production and utilization of substances. The integrative approach combines biogas production, processing fermentation residues and fermenting algae, all in a single facility. Fermentation residues from producing biogas are used to make customized fertilizers and high-grade protein feed. Two-thirds of the remaining fermentation residues are converted into clean water, and the biogas process and the treatment of fermentation residues are used to obtain nitrogen with which to ferment heterotroph algae. In exchange for only 20 % less biogas produced, the process utilizes up to 70 % of the nitrogen accumulating.

Producing heterotroph algae

Utilizing algae for material has huge potential. Microalgae are used to produce polyunsaturated fatty acids on an industrial scale for the food and feed industries; they can also be used as a feedstock in the chemical and pharmaceutical industries. Usually, in phototrophic production, algae need sunlight, carbon dioxide and water to be able to grow. The energy to fix carbon dioxide in photosynthesis comes from the sun. In this process carbon dioxide is fixed in the form of chemical compounds which represent a source of carbon for the algae. Where heterotroph microalgae are fermented, the algae do not need light or carbon dioxide in order to grow; in heterotroph algae cultivation the algae cells are not supplied with carbon dioxide but with other sources of carbon, such as sugar or acetic acid.

Organic waste as a source of protein for aquacultures

In the RERA-pro approach the heterotroph algae are intended to serve as a source of protein (algae SCP = Single Cell Protein) for aquacultures. The aim of the strategy is to cut costs dramatically – the cost of producing SCP is meant to go down by 50 up to 70 %. With a shortage of fishmeal expected all over the world, opening up new, tailor-made sources of feed protein presents a global challenge. This applies to the industrialized countries, too – the EU´s self-sufficiency in feed protein is only 32 %. Heterotroph algae are an ideal substitute for fishmeal; in comparison with vegetable proteins, they have a better spectrum of amino acids, and fish fed on them contain more omega-3 fatty acids.

Producing heterotroph algae from organic waste is a cutting-edge strategy that can help to mitigate the worldwide shortage of sources of feed protein. Implementing a first integrated biorefinery to process residues is planned for 2017, in the form of a research and test facility on the Stipits premises in Rechnitz (Burgenland).

Netzwerk Algen

To encourage research, development and implementation of technologies and products connected with microalgae, bmvit manages Netzwerk Algen (“Algae Network”). Once a year a meeting is held at which the stakeholders in the field can link up together. Apart from activities in Austria, there are plans to exchange information with stakeholders in Germany and Switzerland.

More information is available at:

www.nachhaltigwirtschaften.at

https://infothek.bmvit.gv.at

Share