The European Union aims to make a decisive contribution to Europe‘s international competitiveness, to the reliability of supply and to achieving its 20-20-20 climate protection goals by means of strategies and concrete steps to improve energy efficiency. Large-scale savings are possible mainly in energy-intensive sectors such as buildings, manufacturing industry, energy conversion and transport.

In 2008 the EU member states resolved to cut their consumption of primary energy by 20 %, reduce their CO2 emissions by 20 % from the 1990 level and increase renewables‘ share of total energy consumption by 20 %, all by 2020. In 2012 the EU Commission adopted a new energy efficiency directive aimed at accelerating the rate at which energy consumption is reduced. The directive covers most of the areas in which energy is involved, from conversion via transport to final use, and envisages numerous actions which the member states should take to improve energy efficiency.

Energy-intensive industries such as iron and steelmaking, chemicals and petrochemicals, non-ore mining, glass, paper and printing have a vital part to play in achieving these goals. End-use energy consumption is constantly increasing in these sectors; in Austria it was 40 % higher in 2011 than in 1996. In relation to the production index, though, these sectors were a good 15 % less energy-intensive in 2011 than in 1996. If energy is used efficiently in industrial production processes, significant savings are possible: a vital contribution to achieving energy policy targets. At the same time costs go down and international competitivenesss improves.

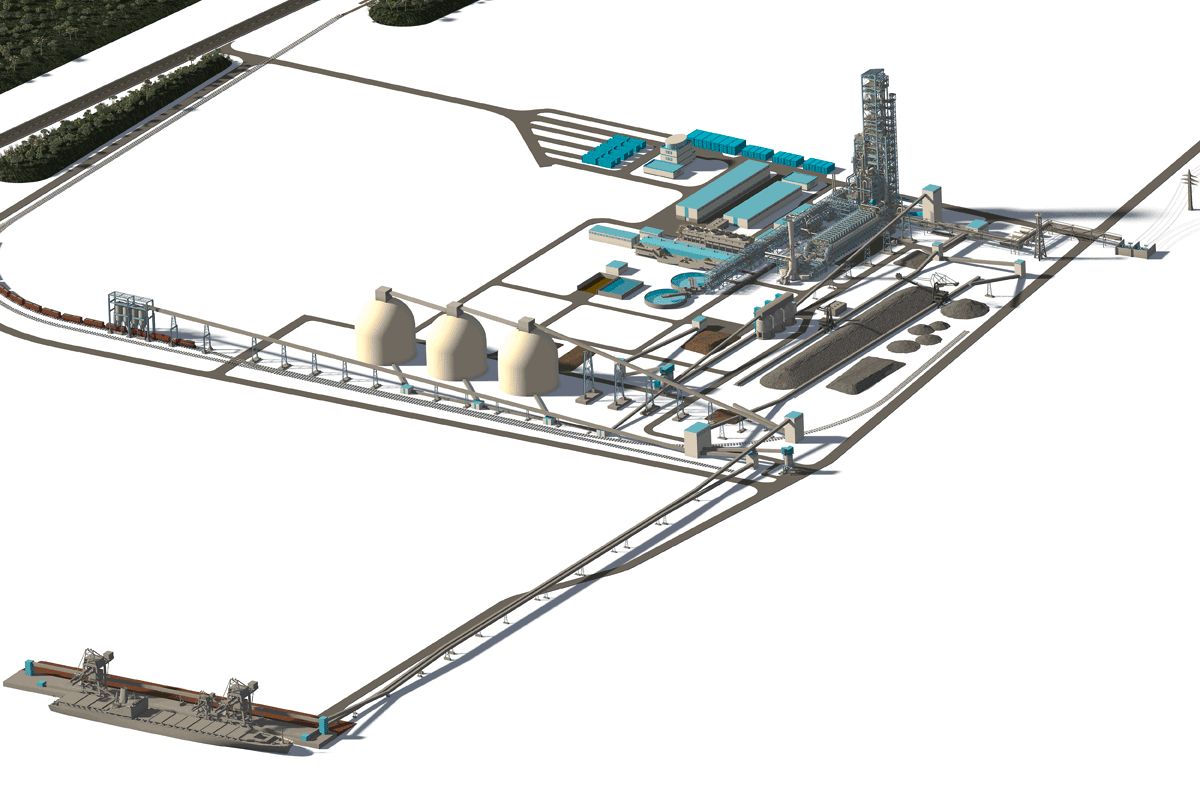

Many industrial processes involve heat, cold and mechanical energy on a large scale. This demand for energy is met mainly by means of fuels and electricity. Because industrial processes are so diverse, there are any number of starting-points for improving efficiency. To take full advantage of the opportunities, new technologies and specially adapted processes are needed.

Today Austrian industry is among the most energy-efficient anywhere in the world. For decades Austrian firms have been developing technologies and products for low-carbon industry, and are doing a great deal to push resource efficiency up, cut costs and thus improve their chances in international markets. In some fields of industry Austrian companies have taken a clear technological lead with cutting-edge innovations. Research and development focussed on using energy efficiently help to buttress Austria and Europe as locations for industry, promote innovation and growth, and create jobs.

As part of the funding programs managed by the Climate & Energy Fund (e.g. New Energies 2020 and e!Mission) and by the Federal Ministry for Transport, Innovation and Technology (BMVIT), projects concerned with innovations to improve energy efficiency in industrial processes are constantly being implemented, and brand-new technologies put to the test in practice.

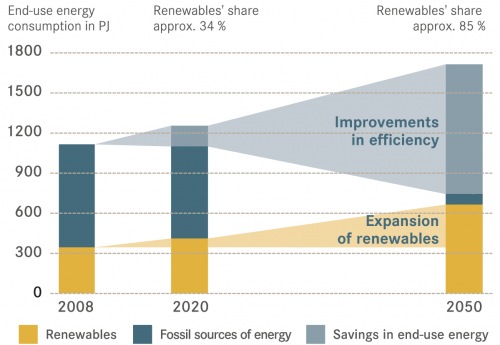

Modelling the development of energy consumption up to 2050

The energy research strategy defined by the Austrian Council for Research and Technology Development in 2010 outlined recommendations for action at national level up to 2050. Improving energy efficiency has been a central aim of Austrian energy research and technology policy for decades, and its importance was underlined again in the Energy Research Strategy (see also interview on page 8).

Share