The projects LIGNO I and II are intended to develop strategies for the complete use of lignified biomass as raw material, they are being carried out by the University of Natural Resources and Life Sciences (known as BOKU), Vienna, denkstatt GmbH and Technologie- und Dienstleistungszentrum Ennstal. Cascading woody biomass is being investigated in the fields of chemistry, wood research and biotechnology, and strategies for developing new materials based on biomass are being worked out.

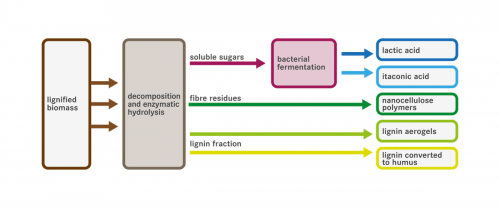

The BOKU Departments of Biotechnology and Chemistry and the BOKU Institute of Wood Technology and Renewable Materials are developing chemical, physical and microbial methods with the aim of obtaining various material streams (depending on the raw material) which terminate entirely in products of economic value. Possible examples include lactic acid for making bioplastics, humus-like fertilizer to improve soil quality, or high-grade nanocellulose fibres. The material streams are mapped in process descriptions and in a business model, with the aim of exploiting the identified processes economically. In the course of the project denkstatt GmbH assesses profitability and ecological impact.

New methods for biomass-based materials

In LIGNO I the researchers were concerned with selecting and decomposing suitable raw materials, and developed new methods of hydrolysing the biomass with enzymes, removing lignin, fermenting with yeasts and obtaining fibres. A number of interesting products were made with the lignins extracted, yielding cues for promising application-oriented follow-up projects. Valuable new insights were gained in the field of fermentation. With the yeast employed, Candida lignohabitans, various sugars and lignocellulose hydrolysate were harnessed to make lactic acid and itaconic acid. This provides an interesting option for making more value of raw materials based on lignocellulose by biotechnological means.

Pioneering product developments

Building on these findings, LIGNO II is developing the chemical and biotechnological path further, to create the conditions needed for launching the new materials commercially. The Austrian Federal Forests and FERMTECH GmbH are also partners in this project.

The focus is on utilizing the lignocellulose biomass in a modular way and on making various products that could only be manufactured from petroleum in the past. For instance, it is possible to make dimensionally stable aerogels (not previously available) based entirely on lignin. Aerogels are ultra-light, highly porous materials with a growing number of technical applications, such as:

> high-performance thermal and acoustic insulation

> substrate for catalysts and filter systems

> electrode material for electrochemical applications

Another interesting chemical is itaconic acid, like lactic acid a precursor for polymers; until now it could be produced only under very specialized conditions. Itaconic acid resembles maleic acid, which serves as a precursor for making acrylates and resins. Both itaconic acid itself and its derivatives can be employed as building blocks in chemical synthesis. For instance, itaconic acid can be decarboxylated and then esterified to make methyl methacrylate, which is then turned into plexiglass.