H2FUTURE is a European flagship project concerned with the production of green hydrogen from renewable electricity for use in the steel industry. Coordinated by VERBUND and in cooperation with project partners voestalpine, Siemens and Austrian Power Grid, as well as research partners K1 MET and TNO, a proton exchange membrane (PEM) electrolyser was implemented at the voestalpine production site in Linz. The PEM electrolyser has a connected load of 6 MW and a production capacity of 1,200 cubic metres of green hydrogen per hour. The green hydrogen pilot plant has been in operation since November 2019.

Renewable energy in industry

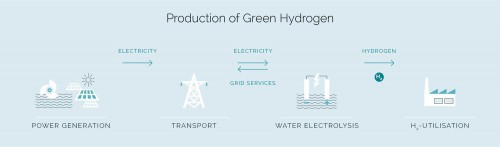

The reduction of ore into raw iron takes place today largely in blast furnaces that use coke as a reducing agent. Although it is highly efficient, this method is associated with emissions of over one ton of CO2 per ton of steel. The iron and steel industry is responsible for 30% of industrial CO2 emissions worldwide. Intensive research is therefore being conducted into so-called breakthrough technologies in order to advance the integration of renewable energy in industrial processes. Green hydrogen has the potential to become an energy carrier of the future, contributing to industrial decarbonisation. The H2FUTURE project is exploring possibilities for replacing coke and coal with green hydrogen as the reducing gas. This could significantly lower CO2 emissions in the steel industry. Electrolysis technology makes it possible to produce green hydrogen with electricity from renewable sources, which is then available as an environmentally friendly energy carrier for various applications in industry and the mobility sector, as well as an energy storage medium..

Project goals

The goal of the project H2FUTURE is to test various “use cases” with the PEM electrolyser. In addition, the system’s potential for providing grid services is being researched. Using demand-side management, the PEM electrolyser acts as a dynamic load-balancing component to help compensate fluctuations in the increasingly stressed power grid. The insights from the project are of great significance not only for the steel industry. The research partners are also investigating the transferability of the findings to other industry sectors where hydrogen is used (such as the chemicals or fertilizer industries). Another aspect of the project is an analysis of the regulatory framework. For this purpose, the H2FUTURE consortium is in regular contact with the stakeholders and other hydrogen innovation projects

EU flagship project

H2FUTURE is a research project subsidised by the European Commission as part of the Fuel Cell and Hydrogen Joint Undertaking (FCH JU), start 1/2017, duration 4.5 years. This project was recognised in 2018 with the “FCH JU success story award”.

More information:

www.h2future-project.eu