While there has been significant progress in energy-efficient construction as well as ecological building materials and recycling in recent years, the environmental impact of construction activity itself has received little attention to date. A recent study by the Resource Management Agency (RMA) and the TU Wien1 focuses on this aspect. Within the scope of the analysis, all directly and indirectly generated CO2 emissions on urban construction sites were identified and methods, technologies and framework conditions for their substitution, compensation and adaptation were shown. These methods include reducing CO2 emissions by shortening the construction time, and optimisation of the process chain in connection with practices such as lean management, as well as CO2 credits for using on-site resources, for example, urban mining. To account for the emissions, construction sites were broken down into individual processes. The respective process steps were assigned to diesel and electricity consumption, transport kilometres or other emission sources. In practice, emissions depend on many other factors as well, such as the location of the construction site, the size of the construction equipment, the construction site logistics and the construction methods used. For the accounting, four fictitious construction sites were taken as samples (building construction, road construction, renovation and demolition site) were defined. Their emissions fully calculated with the help of an expert tool developed in the project.

Strategies for neutralisation

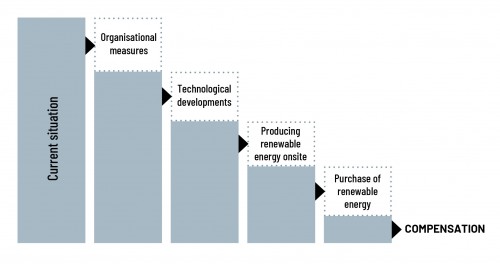

Optimisations in the construction process and the use of low-carbon equipment, machinery and vehicles are the primary strategies to reduce emissions on the construction site. An important measure to reduce CO2 emissions is replacing fossil-based electricity from the grid with locally generated or purchased electricity from renewable sources. Emissions that cannot be reduced to zero should be offset externally as an ultimate step. The study evaluated the different strategies regarding technological availability, effectiveness, implementation costs and realisation complexity. The processes of the model construction sites were compared with the identified measures.

Results and potentials

The scenarios for the four model construction sites show ambi-tious possibilities for reducing greenhouse gases that can be implemented in the short term. From a business perspective, however, not all of these can be considered cost-neutral. The road construction site has the lowest savings potential at ap-prox. 20%. This is due to the more energy-efficient construc-tion processes and machinery. For the demolition site – which has a high transport share – a savings potential of 25-30% was calculated, which could be even higher with more reused on-site mineral demolition material. In the electricity-intensive renova-tion site, the savings potential – mainly through the purchase of renewable energies – is just under half of the emissions. The CO2 emissions of the building construction site could be reduced by more than half. Two-thirds of these results would be due to shortening the transport distances. Alternative drives for construction machinery and transport vehicles are an effective measure to reduce CO2 emissions. Possible sustainable drives of the future are electric power (in batteries, or for stationary construction equipment also via cable), hydrogen/fuel cells, fuels from biomass (as support or transitional solution) and e-fuels (combustion fuels synthetically produced from green electricity).

nachhaltigwirtschaften.at/en/sdz/projects/co2-neubau.php

1 Project partners: Resource Management Agency (RMA) (project management), TU Wien (Vienna University of Technology) – Institute for Interdisciplinary Construction Process Management, Department of Construction Process and Methods

Share