In industry, storage technologies are used to decouple heat generation and heat consumption over time, thereby increasing the efficiency and flexibility of industrial processes. Steam storage systems are a proven and widespread technology that is e.g. used in the food, luxury food, paper and metal industries. By storing and subsequently using surplus heat or waste heat, the total heat generation requirement in the production process is reduced and CO2 emissions are lowered. The flexibility of the processes is also necessary to be able to integrate a high proportion of renewable energy sources. Thermal energy storage systems with much larger capacities than before are needed for decarbonisation and the switch to renewable energy sources in industry.

Innovatives Innovative concept

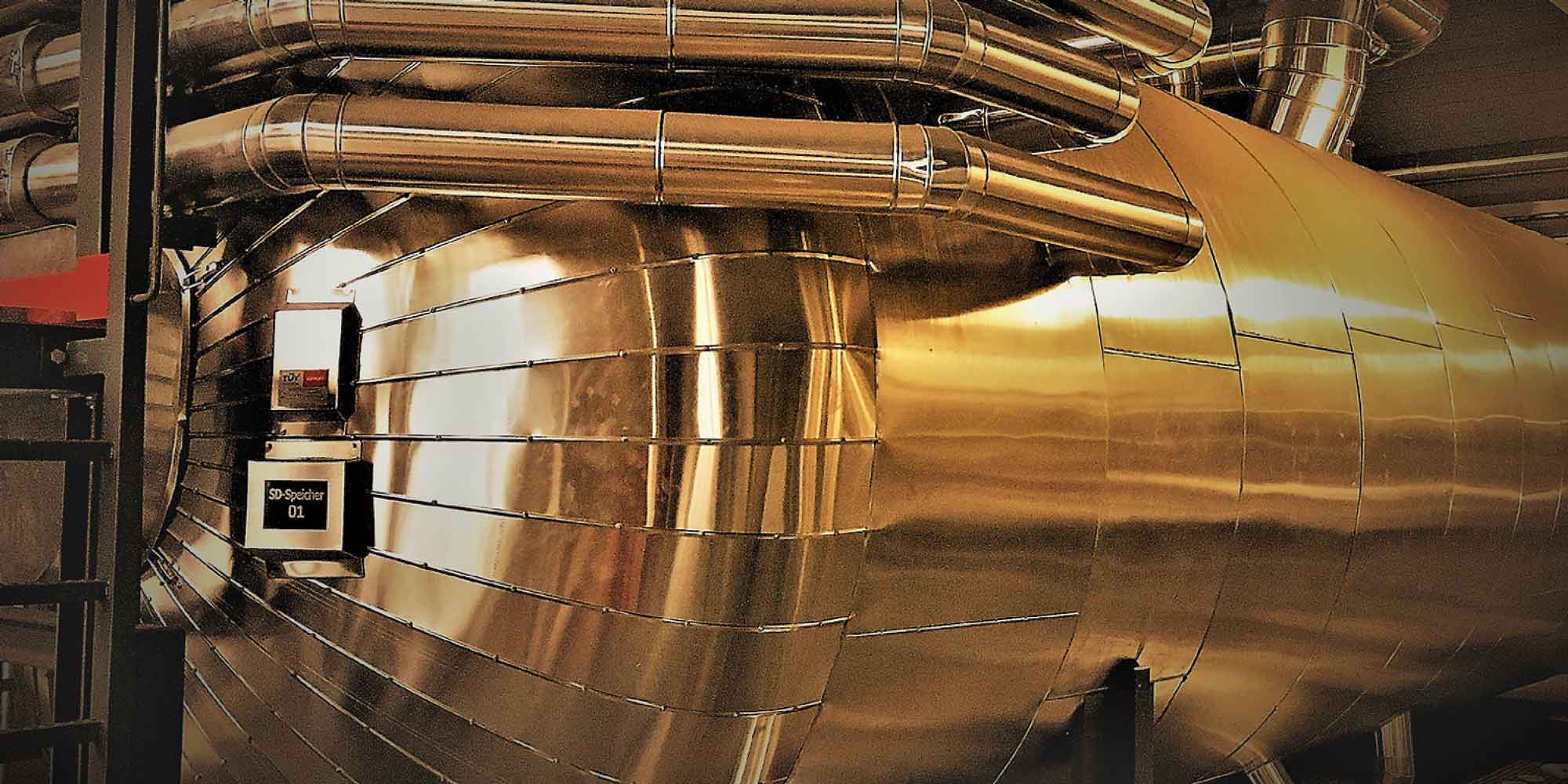

With HyStEPs, an innovative hybrid storage concept was developed and tested in order to increase the storage capacity of “Ruth’s steam accumulators” by up to 40% in the medium term. For this purpose, a storage tank was encased with latent heat storage elements as a laboratory sample. These special storage elements contain phase change material (PCM), in this case technical salt mixtures, which have a high storage density. The PCM sheathing makes it possible to store significantly larger amounts of energy using almost the same design size. The loading and discharge behaviour of the steam accumulator should remain unchanged wherever possible, including with the increased storage capacity. The innovative solutions were developed by a consortium of research and corporate partners led by the AIT Austrian Institute of Technology1.

The following aspects were at the centre of the project:

> thermal connection of the latent heat storage elements to the steam accumulator

> increasing thermal conductivity of the phase change material through heat conduction structures

> corrosion behaviour of the material combinations

> strength calculations

> new methods for mathematical modelling and simulation of the behaviour of hybrid storage systems

Cost-effectiveness

Detailed needs analyses were prepared and initial techno-economic assessments were carried out based on five industrial processes from different sectors. According to the concept, the investment costs for retrofitting an existing storage tank to a hybrid storage tank are only half of an equivalent Ruth’s steam accumulator. Since Ruth’s steam accumulators require a lot of space, increasing the storage capacity with PCM sheathing would present an innovative alternative.

Test operation at voestalpine

The experimental storage system was set up in the laboratory environment of voestalpine Donawitz and is being tested at this location. For this purpose, steam is branched off from the existing steam network and fed into the storage tank under laboratory conditions. Both the steam accumulator and the PCM elements are connected to a variety of measuring devices in order to be able to record the thermodynamic condition of the storage tank at any time and to determine its dynamic behaviour. The plan is to develop the concept further and transfer it to other storage systems based on the knowledge gained here.

www.nefi.at/en/hysteps/

1 Project Partners AIT – Austrian Institute of Technology GmbH (project management), Edtmayer Systemtechnik GmbH, TU Wien/Institute of Engineering Design and Product Development/Institute for Energy Systems and Thermodynamics/Institute of Mechanics and Mechatronics, voestalpine Stahl Donawitz GmbH

A project within the framework of the Energy Flagship Region

NEFI – New Energy for Industry

www.nefi.at/en