2007 Infineon Technologies Austria AG launched an ambitious R&D program in collaboration with ZumtobelLighting GmbH and Tridonic Jennersdorf GmbH, aiming to develop new energy-efficient LED lamps to satisfy the most demanding customers, as suitable replacements for conventional filament bulbs in the mass market.

The flagship project “Future LED Bulb” was aimed at developing LEDs with the following characteristics:

- top energy efficiency

- constant, pleasant colour temperature

- constant intensity

- extremely long service life (approx. 50,000 hours)

- attractive market price

- capacity for dimming by means of existing systems

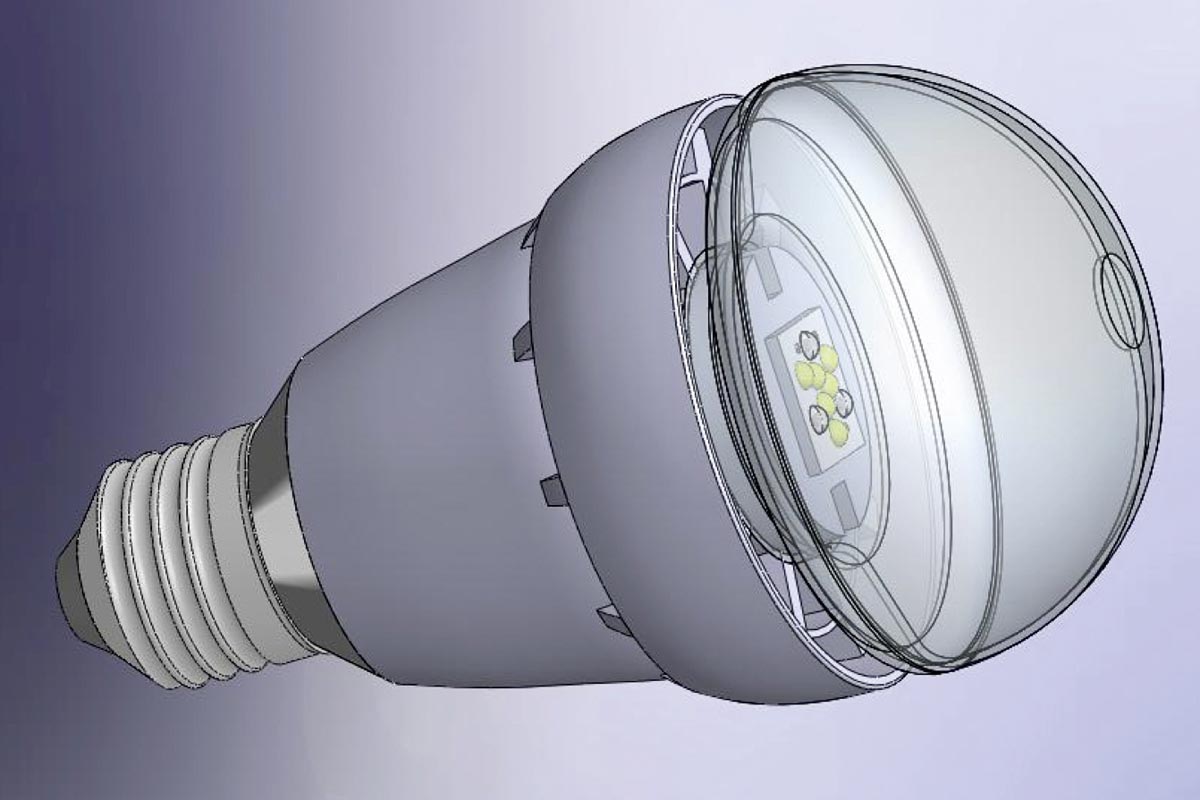

In the course of the project new lamps with an exceptionally long service life were developed; they are equipped with extremely efficient ultra-compact DC converters and low-loss LED drivers with new control algorithms to set colour temperature and stabilize the luminous flux. Further challenges involved attractive design, suitable distribution of light and ensuring that no system components overheat. Heat flow management, the new mechanical design, the LED optics and the power-supply electronics were additional research issues calling for considerable innovation.

As development progressed, the limits of heat flow management at that time were revealed. To implement a compact LED-based alternative to filament bulbs with more than 1000 lumen (roughly equivalent to the luminous flux from a 75-watt bulb), for instance, it was necessary to incorporate an exceptionally quiet active cooling device. This pioneering approach makes it possible to manage the heat flow of LEDs with 2000 lumen and more in miniaturized formats. In response to the EU‘s phasing filament bulbs out, the project partners quickly started deriving marketable products from their research. In 2009 Zumtobel launched a subsidiary, LEDON, to exploit the new developments. Both the luminous flux of the “LED bulb” and the efficiency of the pioneering switching approach still lead the field internationally. With a colour rendering index Ra ≥ 90, the product in question sets a benchmark in the market for alternatives to filament bulbs.

Meanwhile Infineon brought out the ICL8001G LED driver and the corresponding demoboard. With the aid of the upstream control setup developed in the project, the number of components required was reduced from more than 50 to roughly 30. Today the Infineon range in the lighting sector is largely made up of products for LED systems.

A key area of future research will be how to incorporate LEDs into new approaches to energy-efficient office and industrial lighting. As part of the project suitable features have already been developed, to make integration in intelligent, sustainable energy systems feasible. Individually switchable LED lamps fit into daylight dimming systems very well. With the aid of high-tech sensors the shortfall of daylight is computed and the level of artificial lighting matched to current needs; in this way electricity consumption can be reduced by up to 60 %.

Sabine Herlitschka,

Chair of Board and CTO, Infineon Technologies Austria AG