One well-established technology for the generation of electricity and heat from biogenic resources is combined heat and power (CHP) in bioenergy plants. However, the coupling of biomass combustion and ORC or steam turbines can only achieve a very low electrical efficiency of about 10-25%. The electrical efficiency is also limited to about 30% in biomass gasification plants coupled with gas engines.

Efficient and flexible System

In the ERA-NET project BIO-CCHP (Combined Cooling Heat and Power), researchers and industry partners from Austria, Poland and Sweden are working under the direction of the Graz University of Technology1 to develop a new biomass-based CHP technology for the production of electricity, heat and cold that promises a significantly higher electrical efficiency (> 40%), as well as reduced costs compared with typical bioenergy systems. The technology should also offer maximum flexibility in terms of the biogenic fuels used and the operating conditions.

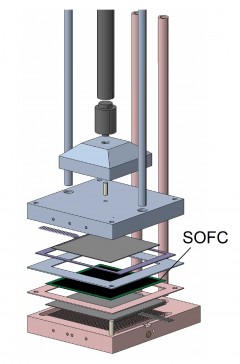

This innovative concept is based on the coupling of a biomass gasification plant with solid oxide fuel cells (SOFC) and a cooling unit. As a result of climate change, a rising need for cooling can be expected in the future (in buildings, hospitals, supermarkets and for the food industry). There are very few biomass combustion plants currently in Austria that can generate cooling from waste heat.

Central research topics

> Optimisation of various gasifier types for coupling with solid oxide fuel cells and for a greater fuel range

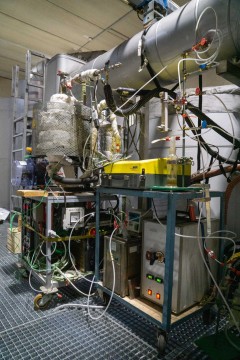

> Development of a mobile high-temperature gas cleaning system for removing product gas contaminants for studies on various gasifiers of the project partners

> Optimisation of the operating conditions of an SOFC for various gas compositions with a long-term test (> 300 h) and CFD modelling to achieve an efficiency of > 40% with maximum fuel cell lifespan

> Solutions for integrating a cooling unit into the process under specific local conditions

The project work will also include an analysis of the raw materials, technologies and obstacles to market introduction in various countries, and the creation of an industrialisation plan. The new technology should enable sustainable and competitive use of biogenic resources and has the potential to make a major contribution to a CO2-neutral energy supply.

35% of the heating demand, 6.4% of the electricity demand and 6.7% of the fuel demand in Austria were supplied by biomass in 2016.

Study “Bioenergy in Austria”, BEST – Bioenergy and Sustainable Technologies GmbH, 2019

Initial results

In the first project phase, the partners’ various gasification technologies were analysed, and an extensive evaluation of gas compositions and contaminants (e.g. tar and sulphur) was carried out. Fuel cells are sensitive to such contaminants in the gas, making the correct treatment of the gas critical for prolonging cell lifespan. Special methods for gas cleaning and improving the product gas quality were tested.

An appropriate fuel cell type was identified and optimal operating conditions for the implementation of an SOFC in the system were defined. A 500-hour operating run with a synthetic product gas from a fluidised bed steam gasifier was conducted, as well as CFD (computational fluid dynamics) simulations. The data that was gathered will help to improve the understanding of the electrochemical processes in the cell and to identify the optimal operating points for efficient coupling of biomass gasifiers with SOFC systems.

www.bio-cchp.net

1 PROJECT partners: Graz University of Technology/Institute of Thermal Engineering, BEST – Bioenergy and Sustainable Technologies GmbH (AT), HARGASSNER GmbH (AT), SynCraft Engineering GmbH (AT), Institute of Power Engineering (PL), Modern Technologies and Filtration Sp. z o.o (PL), RISE Research Institutes of Sweden, Energy and Circular Economy (SE), Cortus Energy AB (SE)