EU directives require that the share of renewable energy in the fuel sector be increased to 10% by 2020. This target is not achievable with established biofuels, as the need for more agricultural land would basically result in direct competion with food production. So there is a quest for new technologies with which to produce second-generation fuels from agricultural and forestry by-products. In the “Biomass to Liquids”(BTL) process biomass containing lignocellulose (e. g. wood chips or straw) is converted into environmentally friendly diesel fuel. As these processes emit less CO2, second-generation fuels also show an improved ecological bottom line.

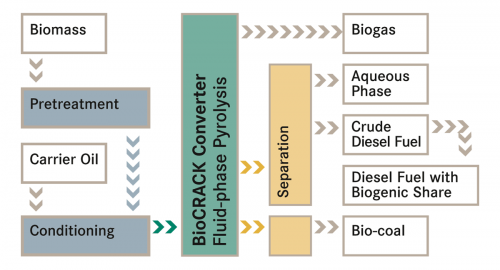

In July 2012 the first BioCRACK pilot plant worldwide (developed together with BDI – BioEnergy International AG) was commissioned at the OMV refinery in Schwechat. The facility employs a new patented fluidizing process to convert solid biomass straight to diesel fuel. The “BioCRACK Technology” makes it possible to achieve a biogenic share of up to 20% of the fuel at source, i. e. the refinery process, through co-processing of petrochemical by-products and using solid biomass. In this technically simple and low-cost process, which is integrated into the traditional oil refinery process, biomass (wood and straw) is heated up to more than 400 °C together with heavy mineral oil. So far heavy mineral oils have mainly been used to make petrol, but in the new facility they can now also be used to produce diesel fuel.

Inside the refinery in Schwechat the BioCRACK test facility is connected directly to other facilities where the chemical product resulting from the BioCRACK process is refined to diesel fuel complying with European standard EN590. The final product is a conventional diesel fuel composed of pure hydrocarbons, suitable for all engine types and with a high biogenic share. In the course of the process no waste is generated, as biogas, bio-coal and other by-products can be used as a source of energy or refined into higher-grade products.

Gerhard Roiss

CEO OMV

Share